Electric Utilities & Power Distribution

Specialized work grounds energy utilities

Energy production and distribution involves unique safety and performance responsibilities. AOG President Allan Bush says that’s why power-producing companies only work with engineering firms they know they can trust down to the details.

“You can trace Alpha-Omega Geotech’s work on the power grid back to our earliest days. We consider it a hard-earned specialization.”

AOG is well known among area utilities with the Board of Public Utilities (BPU) and Evergy at the center of our energy portfolio. From geotechnical investigations and drilling to sampling, lab testing, field testing, and inspections, we provide service that gives utility clients the confidence they need to do incredibly sensitive and important work for the community.

“Power generation is a very, very demanding client,” says Bush. “As a geotechnical firm, you’re not going to play in this game unless you have the right people with the right experience, advanced testing equipment, and the ability to mobilize in difficult natural environments.”

“You can’t be strong in just one aspect of this work,” adds AOG Business Director Blake Bennett. “You have to specialize in all of it and that doesn’t happen overnight. We’ve been at it for decades.”

AOG’s energy portfolio includes several clients and more projects over the years than we can easily count. Our influence ranges from massive power generation stations where electricity originates to smaller substations that help channel it to homes and businesses, and many of the huge steel structures in between that support connecting power lines.

An Essential Spark at Generation Stations

Our technicians are familiar faces at BPU’s Quindaro and Nearman generation stations. We’ve also supported KCP&L stations and take particular pride in our role in helping lead engineering firm Burns & McDonnell with the rebuild of KCP&L’s Hawthorn station. The pre-existing framework gave us a head start but the rebuild still required an extraordinary effort. The inspection of over 2,000 foundation elements (auger cast piles) kept a team of five AOG technicians on site all of the time.

KCPL/Evergy Hawthorn Generation Station

The enormous coal dumper pit at Hawthorn was a big geotechnical engineering challenge. Rail cars dump their loads into the pit just a short distance from the Missouri River. Bush says the close proximity to the river creates buoyancy forces in the ground that push back on anything pushed down into it.

“It’s all flood plain around there and that means sandy soil saturated by water.”

Imagine pushing an empty bucket into a full bathtub. The water tries to push it back up. That’s what AOG was up against in our contribution to the coal pit design plan aimed at countering buoyancy forces.

“We had to make the foundation slab larger than the pit,” says Bush. “We extended it beyond the pit walls to engage the weight of the overlying soil to withstand the upward buoyant forces.”

The rail loop that carries coal cars through the station created another major engineering challenge at Hawthorn. The project plan called for heavy bottom ash, a byproduct of coal combustion, to be used for the entire embankment supporting the train tracks.

AOG took on the geotechnical engineering involved, studied the viability of the idea, validated the supporting data and conducted tests to pinpoint the right density and stability needed to handle the constant stress of rolling coal cars. Bush says the bottom ash approach worked like a charm.

“Credit also goes to Black & Veatch and the greater engineering team for thinking out of the box and making use of the unique materials available. It was a custom solution for an unusual challenge and saved a lot of time and money. It’s exactly the kind of work we love.”

A Spectrum of Services at Substations

Down the line from power generation stations, AOG supports the development of substations in several ways starting with the geotechnical investigation prior to construction. Our geotech work enables a utility engineer to design footings that support massive substation components.

“The ground beneath substations must be thoroughly understood,” says Bennett. “We have to find, identify and describe all of the rock in the subgrade to determine whether the rock is capable of handling all of that weight. You have to know how strong all of the material is to be able to anchor the entire project to it. That’s not something you want to take a chance on.”

AOG engineers then do field inspections, verify soil profiles, check the concrete that’s poured during construction, and conduct other inspections that are typical of our role in construction work. Bennett says precision is the highest priority.

“Our team works closely with the utility’s design team because we have to get everything exactly right. We’re dealing with very heavy structures that are sometimes really tall, too. We help design foundations that are deep and heavy. They’re just huge blocks of concrete in many cases that distribute weight evenly.”

AOG’s expertise helps ensure essential support for massive substation components.

How much electricity the ground around the foundations can take is also critical. Bush says AOG specializes in gauging resistivity.

“It’s for grounding purposes, sort of like a lightning rod on a house that sends a big electrical surge safely into the ground. I started measuring resistivity early in my career at AOG. Electric companies demand it.”

AOG’s recent substation projects include a KCP&L substation near the downtown loop on Charlotte and another one in midtown, east of the Country Club Plaza. We helped establish the tall beautification wall around the substation in midtown. The entire site was originally built on rocky fill dirt that elevated the site above the reach of Brush Creek water. Designers first thought support for the new wall would require expensive, drilled piers that run deep into the earth. But Bush says AOG identified a shallow foundation alternative at a fraction of the price.

“We proposed a foundation of crushed rock wrapped in geogrid reinforcement. It’s a solution we’ve used in other projects under similar circumstances, but you really have to know what you’re doing. It’s less expensive, easier to build and reduces the safety risk posed by overhead lines during construction. Some of the equipment needed to drill piers is really tall and they were looking at having to shut down the substation for awhile to use that equipment, which could have been an inconvenience to customers.”

AOG’s shallow foundation alternative saved time and money in the construction of a substation beautification wall near Troost and Volker.

Heavy Duty Up and Down the Line

Some of our firm’s most extensive electricity utility work focuses on transmission and distribution line structures (T&D). These giant, steel structures support high-tension lines and are typically far bigger than the wood power poles you might see in your neighborhood. KCP&L alone has thousands of miles of T&D lines.

T&D structures commonly require foundations that can run especially deep under each leg of the tower. Geotechnical investigations can be extremely difficult because T&D structures are often located in remote, rugged areas. Bennett says utilities want to keep the towers out of the way as much as possible and align them in straight lines to keep transmission and distribution as direct as possible.

Depending on the size of a T&D structure, each of its legs can require foundations as deep as 40 feet

T&D structures are often located in wooded areas that are difficult to access.

“We work through dense woods, muddy creeks, and thick brush — sometimes all three are in our path at the same location. We have to get in there somehow to do our testing. We rely on all-terrain vehicles. In fact, it’s really the only way we can do that work.”

“We’re having to trek from a road, you know, maybe a mile across a field, and then we carve a path into an area and drill some holes,” explains Bush. “Then we pull all the way out, move down the road and do it again. They’re very slow, laborious and tedious projects.”

Bennett says a geotechnical team simply must be ready and willing to do this kind of work. Dealing with difficulty and the unexpected just comes with the territory.

“We’ve had guys clearing paths with chainsaws just to get our equipment through. We’ve had incredibly sloppy messes along creeks that required winches to pull our rigs out of the mud. Sometimes there are injuries. I remember when a guy lost his balance in a thicket and drove a thorn through his hand.”

Drilling work can be extremely challenging in rugged environments.

Specialized Testing and Equipment

In addition to a long track record and the ability to mobilize in rugged environments, a geotechnical firm needs the right equipment to partner with an electric utility. It’s expensive, requires expert understanding, and is considered mandatory.

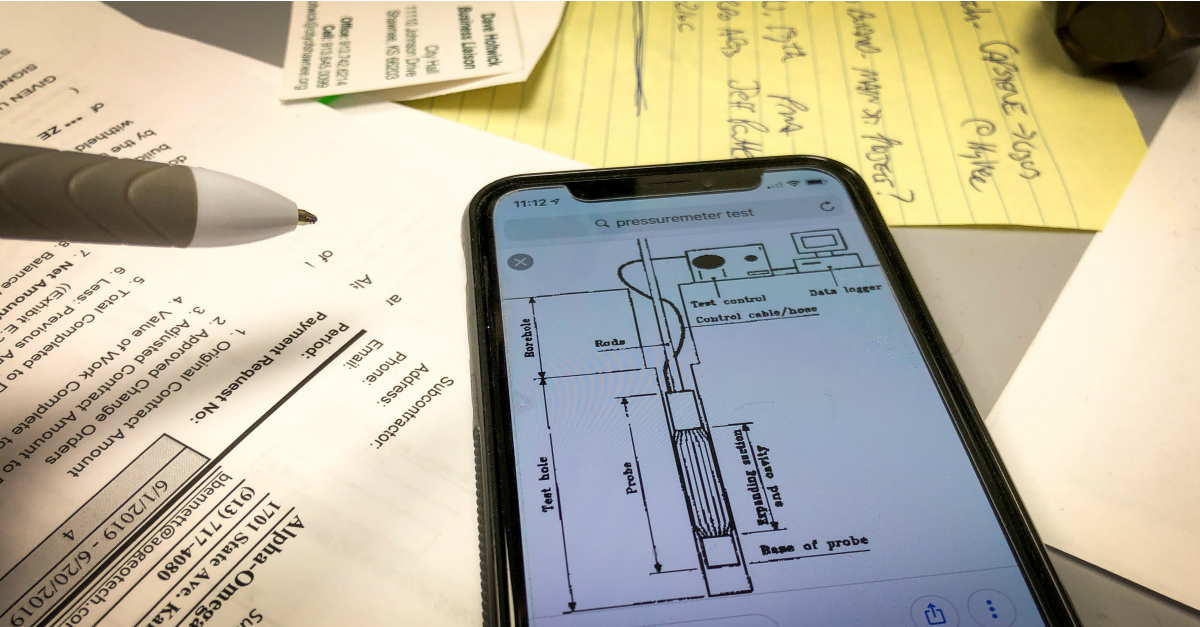

A specialized pressure meter is probably the most important piece. AOG is the only local firm in Kansas City that has one and our engineers have been working with it for decades. Bush’s pressure testing experience is hard to beat.

“In probably my first year on the job, I deployed this meter at over a dozen sites across Kansas, so I have a seasoned understanding of how to work with it and analyze the data.”

Bush shows a simple schematic example of a pressure meter, an essential tool for electric utility geotech work.

The pressure meter evaluates the soil’s capacity to hold T&D structures firmly without the risk of the lines they support ripping the structures out of the ground. It’s hard to imagine the stress these structures are under with heavy lines pulling on them, sometimes from multiple directions. And Bennett says they have to last.

“Lots of tension on both the steel that makes up the structure and the foundation it’s on. And you also have to consider that these structures are expected to hold up for decades through rain, snow, ice, and wind.”

AOG technicians will typically drill five to ten test holes and inject fluid into the pressure meter inside each one to make it expand. The goal is to stress the soil to the point of failure so that utility engineers will know the ground’s exact limits.

The pressure meter is part of the specialized data collection that underscores the way AOG customizes its expertise for utility clients. Engineers at AOG’s laboratory gather unique information required by utility companies and prepare it for input into specialized software utility engineers use to make design decisions.

Specialized data collection and laboratory analysis make AOG the right partner for utilities.

“We’re talking about very advanced soil lab needs that not just any geotechnical firm is equipped to offer. KCP&L engineers know our people will provide exactly what they need for the very specific work they do. They’re depending on us to give them the parts of the puzzle that they can’t get themselves before they piece all of it together.”

Soil testing plays a primary role in utility foundation decisions.

Quality Surges with Collaboration

One thing AOG has learned from all of our experience with utility companies is that working closely with their engineers makes a big difference. Bush believes AOG makes the biggest impact when brought to the table early.

“The more we collaborate with utility engineers, the more they realize the value of our role in supporting power generation, substations and T&D. With our geotech work and inspections, we can ensure the confidence utilities need in everything they build.”

At AOG, we know the benefits of collaboration extend far beyond our work with energy utilities. That’s why we joined the National Utility Contractors Association (NUCA). We want a seat at the table in discussions that solve problems and improve processes across industries. Bennett says NUCA KC is tearing down needless barriers and AOG is proud to be part of the effort.

“We joined NUCA because we have common interests and literally common ground. Utility contractors need the kind of testing and inspection work we do. But most importantly, NUCA KC’S leadership understands the potential of greater collaboration in delivering higher quality work through smarter thinking and better efficiency.”

Mac Andrew, NUCA KC Executive Director (left) and Tony Privitera, Vice President Mark One Electric and President NUCA KC Chapter

A particular source of pride is the fact that NUCA’s Kansas City Chapter is ahead of the curve nationwide in bringing engineers into the mix as members. Bush says AOG is now a leading geotechnical voice in NUCA KC.

“NUCA is the way engineers and contractors can work closer together to not only sharpen internal processes but also help optimize customer processes whether that’s private builders or public works departments. Everyone wins. It’s not about a certain company or discipline furthering its own business agenda. It’s about bringing the highest level of value to those paying for these projects, especially taxpayers. The only way to do that is by rising above the same old process checkboxes and vendor lists to achieve better results through real collaboration.”

Growing with the Grid

In addition to BPU, KCP&L and other electric utilities, AOG’s long resume features a substantial amount of work for natural gas companies including Westar and Missouri Gas Energy. Put it all together and you see more evidence of a pattern reflecting our commitment to the growth of Greater Kansas City. Bennett says contributing to an expanding power grid that parallels an expanding community gives all of us at AOG a true feeling of achievement.

“I think we really are part of the infrastructure. Kansas City can’t grow without power, and you know, we play a role in that. As a hometown company, that’s a big part of our purpose and it’s important to us.”

“This is really what engineers like us do,” adds Bush. “We build the quality of life so that everyone else can go about their lives without even having to think about what happens when they flip a light switch or turn on an air conditioner. We’re a specialized cog in the energy machine that powers Kansas City and we’re very proud of that.”