Olathe Soccer Complex

Turning farm fields into playing fields – Olathe Soccer Complex

Greater Kansas City is widely known as the heart of America and now it feels like we’re building a reputation as the heart of American soccer. Passion for professional and youth soccer is catching fire, further positioning our community as the perfect spot for soccer events that draw people from across the country.

The overwhelming demand for playing fields is kick-starting development on both sides of the state line and sparking creative ideas for supporting soccer fans, players and families. The Olathe Soccer Complex (OSC) is designed as a first-class soccer experience and Alpha-Omega Geotech is proud of helping the grand plan rise from Kansas farmland. AOG president Allan Bush knows the OSC is a win for the community.

“We are contributing to a very big cultural and economic movement, and it’s going to mean a lot to the future of our area including our kids and all the local businesses that will benefit.”

Stretching across 96-acres at K-10 highway and Ridgeview Road, the OSC features nine all-weather fields complete with cutting-edge synthetic turf — the perfect venue for playing out the dreams of hundreds of thousands of young soccer players. In addition to meeting the demand for playing space, the OSC is packaged as a destination with two hotels and over 27,000 square feet of retail. Local and traveling soccer families will have a lot to enjoy right next to the fields.

West Star Development is developing the project along with Ridgeview Associates LLC. West Star’s Mike Christie says the OSC represents a key piece of Johnson County’s future.

“There’s a boom going on at K-10 and we’re right in the middle of it. We believe the Olathe Soccer Complex will bring 1.5 million people to the intersection of K-10 and Ridgeview every year. We saw the area’s growth coming 20 years ago and it’s exciting to now see it taking shape.”

Heartland Soccer Association operates the OSC, building on its long history in Kansas City and its status as the largest soccer league in the U.S. The organization has signed a lease that extends a whopping 25 years into the future and expects to easily book 18,000 hotel nights every year.

Heartland Executive Director Shane Hackett says OSC fields were already reserved by local teams before all fields were even finished and before the hotel and retail construction began.

“The local demand is already so strong and then we’ve got league play and tournaments that draw huge numbers of people to town regularly. A typical Heartland tournament can involve more than 400 teams from 12 to 16 states. Those teams already fill up 15 or 20 hotels across our area so they will welcome the chance to stay, eat and shop near the fields.”

Olathe Soccer Complex fields help meet the skyrocketing demand for playing space.

Transitioning Farm Fields to Soccer Fields

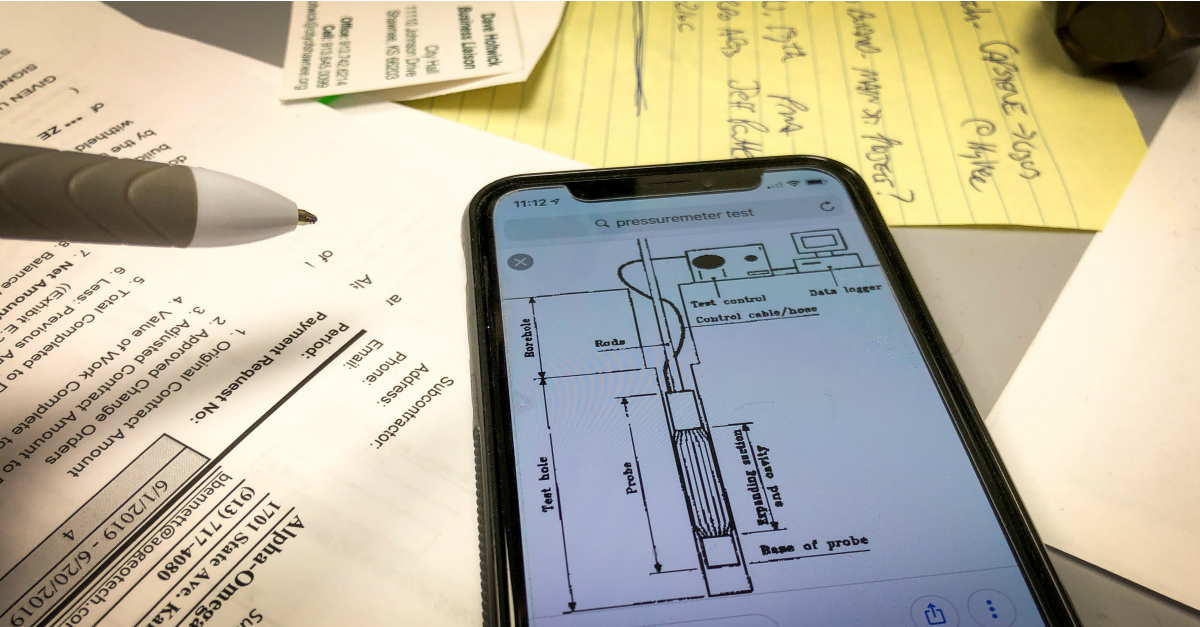

AOG’s work on the OSC started back in 2016 with the investigation of empty farmland in the Kansas countryside. Engineers drilled and dug test pits to get a grip on what the land could offer a project rooted in rigid soccer turf specifications. Hacket says the artificial turf on OSC fields is world-class.

“It’s the highest quality soccer turf. We’re fortunate to have our kids playing on a surface that’s literally the best out there.”

All-weather turf at the Olathe Soccer Complex eliminates soggy delays and muddy destruction.

AOG’s Allan Bush says the turf surface depends on all the layers beneath it and that’s where AOG’s work is especially critical.

“There are very specific layers required with certain thicknesses and qualities for this field to come together exactly the way it should. The turf manufacturer needs precise levels, grading, and support layers. If you don’t get everything just right and stability is a problem, you can imagine what that means.”

AOG quickly identified sloping terrain. The area had to be literally reshaped and leveled with a plan that would ensure dirt wouldn’t settle on the low end over time. AOG recognized the key role of a retaining wall and turned it over to Milburn Civil Engineering for design.

There was also a challenge in figuring out how much rock was buried in the dirt and how hard it would be to dig up and move around. AOG Business Director Blake Bennett says dealing with rock can involve anything from a shovel to explosives.

“There are gradations of everything and rock goes from something soft that you can dig with a shovel to something that’s removable with a backhoe or bulldozer, taking into account the wear and tear on the machines. And then there’s the really hard stuff that you just can’t move mechanically and must be blasted.”

AOG helped civil engineering firm Payne & Brockway understand what they were up against. Payne & Brockway Project Manager Chad Porter says what they found is typical of farmland in this area.

“There was a lot of rock. We were lucky in that much of the shallow rock was soft limestone and shale that could be removed mechanically with a bulldozer. There was some blasting, too. Fortunately, it was pretty limited and focused.”

*Rocky dirt is a typical inconvenience in the Kansas countryside.

Experience Between Rocks and a Hard Place

It turns out the dirt at the site was riddled with rocks to depths of 30 feet in some areas. That isn’t good news when you’re focused on keeping a project economically viable. Ideally, you want to make the most of existing land rather than spending time and money to haul it away and truck in something better.

Other geotechnical firms would likely default to the more expensive export-import approach because rocky dirt is extremely hard to position evenly and comes with the risk of settling. The result can be uneven field surfaces and the formation of dips or ‘birdbaths’ that fill with rainwater. It’s just not worth it unless you really know what you’re doing. Bennett says AOG engineers know exactly what they’re doing and tackled the conditions with confidence.

“We have established a reputation for handling rocky fill dirt and excel at using it efficiently and economically. We’re not afraid of it because we have the right engineers with the right experience to get the job done right.”

AOG worked closely with Payne & Brockway to map out a plan using existing land at the site, rocks and all. Porter says special consideration was given to clay, too.

“The potential of clay to shrink and swell beneath the surface of the soccer field was a factor. The subgrade needed to be rigid so it doesn’t move and literally change the soccer field.”

Olathe Soccer Complex field surfaces are smooth and level and built to stay that way.

What followed was a massive earth-moving project by general contractor Clarkson Construction. It’s hard to even imagine the amount of dirt involved or what was required to move it into place to ensure level, resilient soccer fields that last. Allan Bush says when it comes to engineering major earth-moving projects, his team shines.

“You don’t usually see projects that move this much material. The sheer volume of fill dirt is hard to comprehend and we love the engineering challenge.”

Pictured: Clarkson Construction mobilizing earth-moving equipment for the $65 million OSC project.

Pictured: Clarkson Construction mobilizing earth-moving equipment for the $65 million OSC project.

A Rising Role in the Market and the Community

Beyond the subsurface investigation and geotechnical report, AOG could be called in to test materials and structural components as the rest of Olathe Soccer Complex construction unfolds, rounding out an effort that plays to the firm’s strengths and sends exactly the right message about the value of their experience. Bush believes land developers, architects, and construction companies are taking note, especially in the area of recreational and sports facilities.

“We’re involved in other big soccer projects and we’re also very proud of our work on Rock Chalk Park in Lawrence, widely regarded as one of the largest sports venues in the Midwest. Our track record is hard to ignore and the role of experienced geotechnical engineering is a rising priority.”

Bennett is quick to add that the purpose behind these kinds of projects brings satisfaction that surpasses even the engineering achievements.

“We are a group of local people who are excited to be involved when our community takes steps toward long-term health and happiness. That’s what it’s all about. We’re not only helping to engineer those steps, we’re also growing our hometown and creating a future that will make a difference for generations to come.”

Olathe Soccer Field – Services Provided by Alpha-Omega Geotech:

- Subsurface investigation

- Geotechnical engineering evaluation of the project site (which involved a considerable amount of earthmoving!)

The development of the new soccer park also required several retaining wall structures due to the slope and grade changes across the site. We hired Milburn Civil Engineering to design those structures.

Project Partners:

West Star Development

Clarkson Construction

Milburn Civil Engineering

Payne & Brockway