Kansas City’s urban core is coming alive with new development enthusiasm downtown now rolling into the Crossroads on the success of the KC Streetcar. But before project plans can get off the ground, the unusual Crossroads subgrade full of natural surprises and man-made complications must be put under the microscope. As we continue our blog series focused on the Crossroads, here’s a look at why the right geotechnical partner is critical for positioning construction on a fast track and keeping it there.

Investigating the Unknown

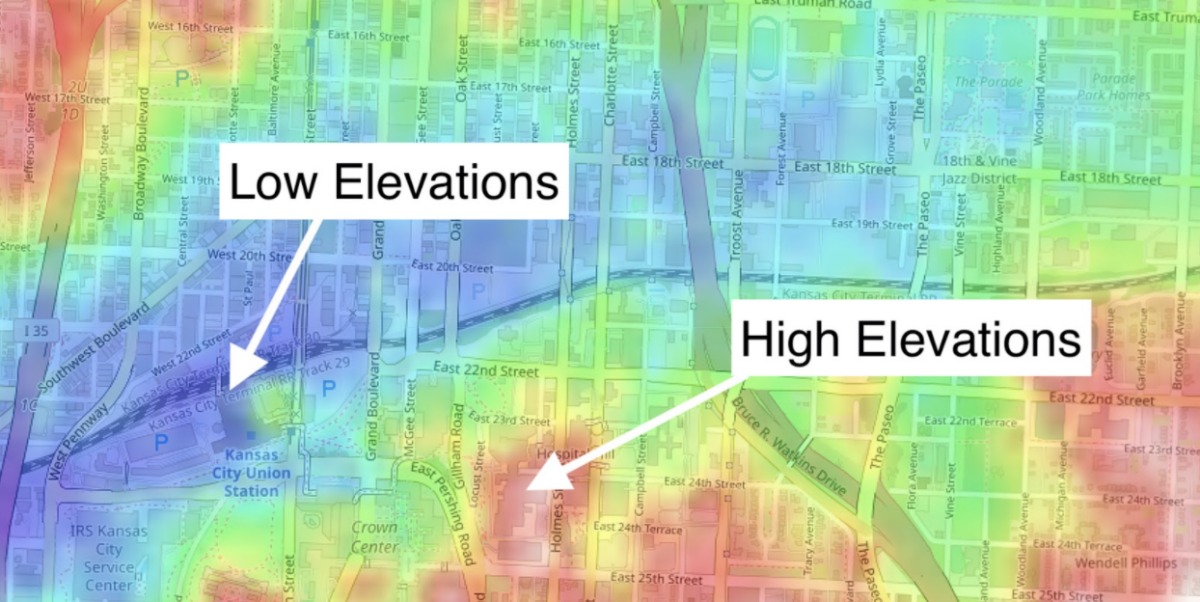

Pick a spot just about anywhere between the high ground along I-670 on the southern edge of downtown and the bluffs around Liberty Memorial and Union Hill, and you’ll find a host of complicated subgrade conditions. Bedrock may be just a couple of feet beneath the surface or more than 150 feet down thanks to millions of years of water, erosion, and other natural forces that just happen to converge in the area.

The same forces left behind permeable rock materials that can trap groundwater at various levels and create messy delays when construction crews cut into perched water tables. In addition, soil types range from clay to poor quality fill, and conditions vary widely across the area. “It’s a very complicated subgrade that can’t be mapped out in advance without testing and specific analysis,” says AOG President Allan Bush. “You’ve got to drill at every potential project site and find out exactly what you’re working with. And expect the unexpected.”

A topographic map shows how land elevations can vary hundreds of feet across short distances in the area with inconsistent bedrock elevations and varying ground materials underneath.

AOG is known for a unique ability to get good boring that delivers meaningful samples for analysis. We pinpoint everything from ground material strength and resistance to saturation. Our crews are ready to go as deep as a hundred feet or more, effectively drilling through any groundwater along the way and actually testing conditions during the process before we even send samples back to the AOG laboratory for advanced analysis. “We can field anything the Crossroads throws at us,” says Bush. “Even if we have to dig test pits and bring in heavy excavation machinery to move things out of our way.”

Alpha-Omega Geotech drilling crew

Alpha-Omega Geotech drilling crew

Adding to the natural complexity of the area are man-made complications. A chaotic mess of sewer and water pipes, fiber cables, and all kinds of buried industrial relics can be found in layers stacked as deep as the bottom of nearby rivers. It’s all been patched together over generations dating back to the 1800s and documentation is hit and miss at best. Much of the mess is surrounded by ‘urban fill’ or debris pushed into the ground over decades of demolition and construction.

“Opening up the ground in any location around that area amounts to an archeological dig,” explains AOG Business Director Blake Bennett. “You just don’t know what you’ll find and it’s everywhere down there. Demolition rubble, broken up concrete, bricks, topsoil, roofing materials, and even things like vehicles, dead animal carcasses. We’ve encountered all of that before.”

Kissick Construction carefully navigated a complicated underworld during the construction of the first phase of the KC Streetcar line.

The subgrade in the heart of the Crossroads around Union Station is an especially deep mystery with bedrock diving far below the surface. That’s where OK Creek was converted to a concrete sewer diversion tunnel and buried about a hundred feet down in preparation for the construction of Union Station.

Huge amounts of fill soil were needed to cover the tunnel. Even more fill had to be shifted into place for surrounding construction. Just look at the site as Union Station construction got underway and you can see how much the subgrade was tortured by men and machines, leaving behind uncertainties and inconsistencies for future builders to navigate.

1911 early view of the Union Station construction site shows a scarred landscape heavily manipulated and dramatically reshaped by human hands. OK Creek is still visible in the foreground. Photo courtesy: Missouri Valley Special Collections, Kansas City Public Library, Kansas City, Missouri.

While our geotech team’s investigative help is critical before you dig at a project site, it may be even more valuable before you choose a site. Bush says he always welcomes the opportunity to help builders identify sites that are likely to offer the kind of conditions they need for the structures they’re planning. “The land acquisition phase is the ideal time to engage us. We can provide key information that can tilt the scales when you’re evaluating different options to make a real estate decision.”

“Big factors need analysis before you choose a property,” adds Bennett. “Things like shallow rock, high groundwater levels and poor fill material have to be weighed in context of your overall budget. Shallow rock means you’re going to spend more to put in utilities because they’ll have to run through the rock and that can mean blasting an opening. Other complexities can include water saturation that’s going to complicate things when you put in a foundation.”

Bedrock levels and layers vary across the area and can be as shallow as a few feet below the surface.

AOG has helped get dozens of projects out of the ground in downtown Kansas City and the Crossroads. We’ve seen more than enough to know that thorough investigation and analysis is the only way to launch a construction plan with confidence that it won’t get bogged down. Can you afford it? Bush says the bigger question is: can you afford to skip it? “If you think being informed about the subgrade is expensive, try ignorance. We’ve seen the results.”

Creative Solutions for Custom Challenges

After a site is chosen and the subgrade investigation is complete, our geotech engineers will recommend the best way to support your structure based on the specific conditions you’re up against. If bedrock is too low to make traditional piering feasible or ground material is too uncertain, we’ll explore creative solutions for intermediate or shallow foundations.

Depending on the size of the structure, maybe the solution is a snowshoe-like support platform consisting of engineered-controlled fill wrapped in geogrid that effectively absorbs and distributes weight at a shallow level. Or maybe the right approach involves geopiers at intermediate depths, filled with pressurized rock to strengthen the ground and improve stability without going all the way down to bedrock.

Regardless of the way we customize solutions for each project, understand that AOG solutions are creative — not experimental. We know exactly what we’re doing. While other firms are more inclined to stick to conservative and often more expensive solutions in complicated subgrades, we’re not afraid to design other options that are more aligned with project goals.

“It’s about making the most of what you have at the site,” Bush emphasizes. “We focus on harmonizing a solution to the conditions the ground offers rather than forcing a cookie-cutter approach. Our ideas don’t exist in a vacuum. We consider the broader context of the project to make sure our thinking fits in well with overarching project priorities.”

AOG President Allan Bush on the job with our crew in the field.

AOG’s focus on efficiency and speed without sacrificing quality extends to the role of special inspections. We do our best work when we apply our expertise from start to finish (from the Alpha to the Omega) and that includes ensuring plans are strictly followed by watching, testing, and confirming the details of construction. Our engineers and technicians are a tight, experienced group, staying in close communication during construction to validate materials and actions, and quickly field any surprises that arise. We know each other well and work closely together to nail down and streamline the entire effort from investigation through construction.

“Our technicians have been on the job for decades. They understand and fully appreciate that our critical engineering calculations are made based on their measurements,” says Bennett. “They’re the eyes and ears of our engineers and perform in a way that strengthens the overall trust our project partners value. The quality that comes with the continuity we deliver as a team is a source of pride for all of us at AOG and clearly makes us different from other firms.”

AOG techs conduct key materials tests and collect samples at precise times during construction.

Go With A Team You Can Count On

An exciting development plan in the Crossroads area shouldn’t be overshadowed by lingering mysteries in the subgrade that come back to haunt you with delays or worse. We believe no one should build in the heart of Kansas City proper without highly specialized geotechnical assistance from the beginning.

The role of geotech is valuable in all construction projects, but the Crossroads subgrade elevates it even more. There’s just too much variation, uncertainty, and risk to make assumptions or take chances. And partnering with AOG means additional peace of mind that unusual subgrade circumstances will be overcome within the parameters of project goals and realities.

If you’re ready to jump into the development bonanza already in full swing in downtown Kansas City, go with the team that delivers confidence far beyond building codes. Our team is well-equipped with local expertise, refined experience, and a collaborative spirit and we know you can’t leave anything to chance when it comes to your development investment.